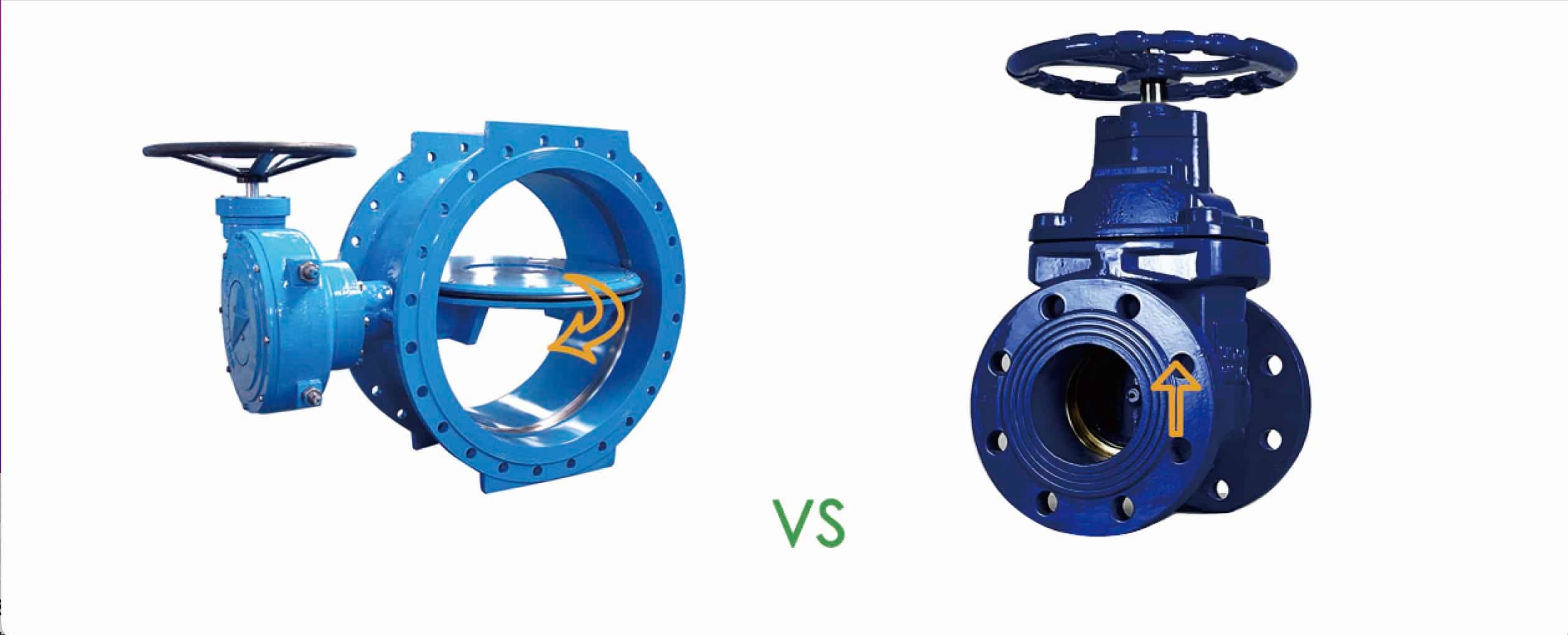

Gate Valve VS Butterfly Valve: Key Differences

Piping systems should have valves. They promote flow, or control, or stop. There are two popular types, which are gate valves and butterfly valves. They are both popular with varied designs and purposes. In order to select the right valve, it is worthwhile knowing the differences. The following guide will describe the gate valve vs. the VS butterfly valve in simple words.

What is a Gate Valve?

A gate valve is a valve that seals a direction of flow using a sliding wedge/gate. The gate rises and fluid flows when it is unclosed. The gate is closed by moving down and sealing the pathway. Gate valves are applied most of the time where the flow should be either closed or open.

What Is a Butterfly Valve?

Butterfly valve employs the use of a rotating disc. All it takes is 3 turns, and it either opens or locks. It is portable, not heavy, and affordable. Generally, a butterfly valve manufacturer would provide numerous varieties of valves to the various sectors.

Design Differences

- The two valves have quite different designs.

- A Gate valve maintains its vertical gate that moves the gate either up or down.

- A Butterfly valve consists of a rotating disc in its body.

- This difference in design alters their working and employment.

Comparison in Space and Weight

- Gate valves weigh more and are space-consuming.

- Butterfly valves are not heavy and occupy less space.

- This renders butterfly valves more appropriate for be utilized in systems that have less space.

Operation Speed

- Gate valves require several turns to fully close or open.

- Butterfly valves only require a quarter–turn to be used.

- Butterfly valves thus run quickly and conveniently.

Leakage and clamping

- A Gate valve offers an extremely tight seal.

- The butterfly valves also seal well, but they can leak slightly.

- The gate valves are usually preferred in high-pressure systems.

Flow Control

- Gate valves are deemed to be the most appropriate when it comes to on-off control.

- A Butterfly valve can control the flow by remaining partially open.

- This increases the level of flexibility of the butterfly valves in most industries.

Cost Differences

- Gate valves tend to be expensive.

- Butterfly valves are less expensive to maintain and cheaper.

- That is why numerous industries use the butterfly valves in large pipelines.

Gate Valve Uses

Gate valves find use in:

- Pipelines of oil and gas

- Power plants

- Chemical plants

- Marine industries

- They are selected under conditions of high pressure and high temperature.

Butterfly Valves uses

The butterfly valves are mostly used in:

- Treatment and supply of water

- Food & beverage plants

- HVAC systems

- Small-med pressure pipeline

- A known butterfly valve manufacturer may offer numerous designs to suit the industry.

A List of Comparisons

A brief overview of gate valve VS butterfly valve goes as follows:

- Design: Gate opens and closes (goes up and down), disc spins.

- Space: The heavy gate valve is light, and the butterfly valve is heavy.

- Operation: slow gate, fast butterfly valve.

- Sealing: Gate valve is more, butterfly valve is medium.

- Flow control: Gate valve opens/closes, butterfly valve controls flow.

- Price: the price of Gate valve is high whereas butterfly valve is very low.

Comparison Table

| Feature | Gate Valve | Butterfly Valve |

| Design | Sliding gate or wedge | Rotating disc |

| Space Needed | Large and heavy | Compact and lightweight |

| Operation | Multi-turn handwheel | Quarter-turn handle/actuator |

| Sealing | Very tight | Moderate, reliable |

| Flow Control | Best for on/off only | Can regulate and stop the flow |

| Pressure Handling | Suitable for high pressure | Best for low to medium pressure |

| Cost | Higher cost | Lower cost, affordable |

| Common Use | Oil, gas, power plants | Water, HVAC, food, chemicals |

A List of Top Advantages

Gate Valve

- Excellent sealing

- Handles high pressure

- Long shelf life

Butterfly Valve

- Pact, light

- Rapid 60 degrees per turn operation

- cheaper and easier to install

Conclusion

Gate valves are important, and so are butterfly valves in regulating the passage of a flow. One depends on the needs of the system. When a tight seal and high pressure are needed, a gate valve is preferable. Butterfly valves are the most suitable when speedy functioning, reduced design, and lower price are essential factors. Being familiar with the contrasts between gate valves and butterfly valves can guide the industries to make the right choice. The best place to get quality is by choosing a reputed butterfly valve manufacturer or supplier of gate valves.