How to Disperse Carbon Nanotubes: 3 Key Methods Explained

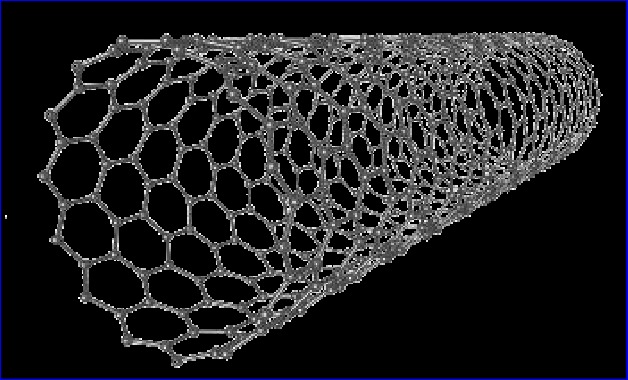

Some of the most interesting nanomaterials that exist currently are Carbon nanotubes(CNTs). They have magnificent strength, elasticity, and electrical conductivity. Thus, they find application in aerospace, electronics, medicine, and energy storage. But a major problem is that of using them efficiently. The forces between the atoms in the CNTs are very large: this causes them to naturally bind together. Such clumps render it very hard to mix them uniformly in liquids or polymers, or any other media.

To release all their potential, scientists and engineers dwell upon carbon nanotube dispersion. A dispersion of CNTs is achieved by this process. The specifically distinctive properties of CNTs could not be completely employed without the proper dispersion. In this guide, we will discuss the importance of dispersion and discuss three major approaches to CNT dispersion.

Why Dispersion is Important in CNT Applications

Under bonding, CNTs lose conductivity since they lose the surface area. Bundled CNTs also lower the mechanical strength and weaken the composites. Well-dispersed CNTs enhance:

- The mechanical characteristics (strength, toughness, flexibility)

- Electrical conductivity (improved sensor performance, circuit performance)

- Heat spread (thermal conductivity in electronic equipment)

- Stable coatings, paints, and composites

It is also relevant to cooperate with a well-established carbon nanotube manufacturer. Because dispersion directly influences performance. High-grade CNTs can be dispersed more easily and result in superior outcomes.

Ultrasonication Method 1:

Ultrasonication involves the disaggregation of the CNT bundles. By the use of high-frequency sound waves in a liquid suspension. The vibrations cause the formation of minute bubbles, which rupture explosively. Causing the separation of nanotubes.

Advantages

- Easy and common Established

- Successful on both single-walled and multi-walled CNTs

- Gets along with solvents, surfactants, or polymers

Disadvantages

- Sonication will also cut CNTs too short. Or otherwise destroy their structure when the sonication is too long in diameter.

- This one is time and power-sensitive

- The most popular method is to prepare a stable carbon nanotube dispersion. Particularly on the lab scale, ultrasonication is.

Method 2: Mechanical Mixing

Mechanical involves using the physical ability to stir, mill, or high-shear blend the CNTs in a medium. This uses an adequate force to disaggregate the bundles and distribute them uniformly.

Techniques Include

- High-shear mixing: Agitated breaking up: A vigorous mix provides strong forces to break clumps.

- Ball milling: In this technique, the grinding contact between CNTs and other compounds breaks and recombines them.

- Three-roll milling: A three-roll mill is used to dispense CNTs in pastes or polymers by compression and shear stress.

Advantages

- Suitable for processing large quantities

- May be used together with heat or solvents

- Appropriate to prepare CNT composites.

Disadvantages

- It can destroy the CNT structure in case too much force is used.

- Usually needs surfactants or polymers to stabilize the dispersion.

- The technique is common among sectors where increasing the volume of production matters. e.g., plastics, coatings, and batteries.

Chemical Functionalization, Method 3:

CNTs are modified by adding chemical groups (chemical functionalization) to their surface. These groups render CNTs more soluble in liquids/polymers so that they do not add.

Functionalization and Types of Functionalization

- Covalent functionalization: Chemical functionalization is done on the CNT surface.

- Non-covalent functionalization: The CNTs are covered by surfactants, polymers, or biomolecules, but do not change them.

Advantages

- Formulates highly stable dispersions

- Enhances water-solubility or organic compatibility

- Increased medicine, coating, and electronic applications

Disadvantages

- CNT properties can be ruined in covalent methods

- Putting to shame the mechanical ways, more elaborate and expensive than they are

- When a long-term, high-quality carbon nanotube dispersion is needed. Chemical functionalization is relied upon extensively.

Major CNT Dispersion Techniques

- Ultrasonication: It is used to break up CNT bundles via sound energy.

- Milling / High-Shear Force: Applies high force to clumps and dispersion.

- Chemical Functionalization: It adds chemical groups to give a stable dispersion.

Conditions that Alter Dispersion of CNTs

- The kind and grade of CNTs (single-walled vs. Multi-walled)

- Solvent/surfactant selection

- Technique of dispersions applied.

- Processing conditions (time, temperature, mixing power)

- Target use (electronics, composite, medicine)

Conclusion

Carbon nanotubes are impressive materials of the future. Yet, the inclination to agglomerate gives some importance to carbon nanotube dispersion. When it comes to effective use. Each of the three major approaches, ultrasonication, mechanical mixing, and chemical functionalization, has different advantages and disadvantages. The appropriate method is determined by application, scale, and material requirements.

With the help of a proven carbon nanotube manufacturer and an appropriate dispersion strategy. Industries can leverage all that CNTs have to offer in flexible electronics and sophisticated aerospace composites. When techniques are perfected, CNTs will remain to define the aspects of materials science.