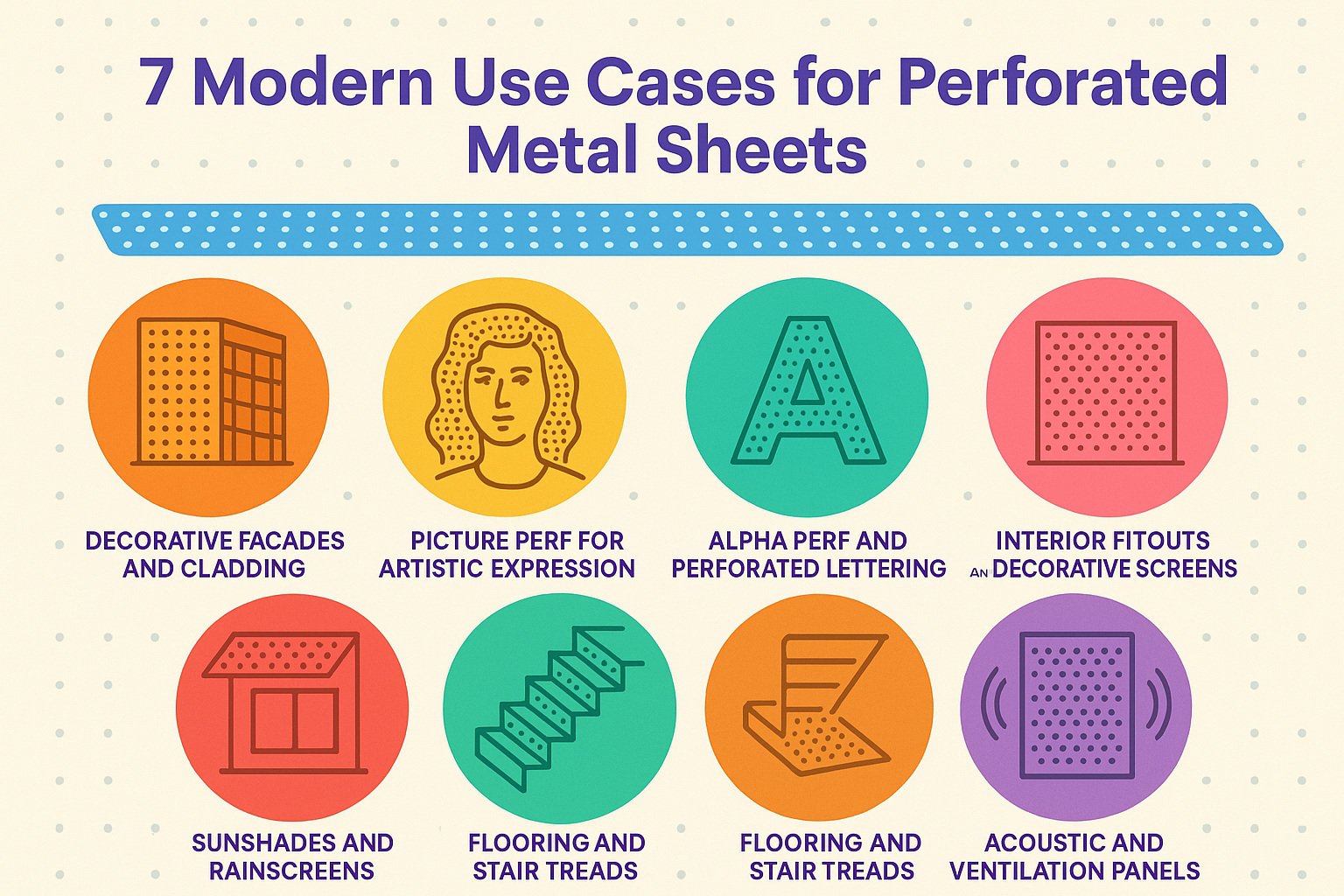

7 Modern Use Cases for Perforated Metal Sheets

Perforated metal has become a design staple across industries. Once used mainly for practical applications like filtration and ventilation, it is now valued just as much for its visual appeal. With modern manufacturing techniques, perforated metal sheets can be customised in almost any shape, pattern, or finish, making them suitable for both architectural and industrial projects. Here are seven modern ways this versatile material is being used today.

1. Decorative Facades and Cladding

Architects increasingly use perforated metal to give buildings a distinctive and modern appearance. These sheets can serve as cladding panels or decorative facades that provide both form and function. Patterns can be customised to reflect brand identity, artistic concepts, or natural light patterns. Materials like corten steel and aluminium are popular choices for their durability and aesthetic appeal, adding depth and texture to a building’s exterior while protecting the structure beneath.

2. Picture Perf for Artistic Expression

Picture perf, where images are recreated through precision perforations, is a striking way to blend engineering and art. This method uses thousands of carefully placed holes to form detailed portraits, landscapes, or logos on metal sheets. It is widely used in public art installations, architectural features, and commercial spaces that want to make a bold visual statement while maintaining the functional benefits of perforated metal.

3. Alpha Perf and Perforated Lettering

For signage and branding, perforated lettering, known as alpha perf, offers a modern alternative to traditional cut-out designs. The letters are formed using small perforations, allowing light and shadow to interact naturally. This technique is ideal for corporate buildings, retail fronts, and interior spaces where subtle branding and texture are desired. It also allows for backlighting, adding another dimension to the finished design.

4. Interior Fitouts and Decorative Screens

Perforated metal has become a favourite in interior design, particularly for partition walls, ceiling panels, and decorative screens. Stainless steel and brass are often chosen for these applications because of their sleek appearance and ability to reflect light. Beyond aesthetics, perforated panels help manage acoustics and airflow, making them both beautiful and functional. In hospitality, office, and retail environments, they create a sense of openness without sacrificing privacy.

5. Sunshades and Rainscreens

Perforated metal sunshades and rainscreens are designed to protect buildings from the elements while improving energy efficiency. These systems allow airflow and light penetration while reducing heat gain. Corten steel and aluminium are frequently used for these applications due to their weather resistance and longevity. The patterns can be tailored to achieve specific shading effects, combining architectural style with practical performance.

6. Flooring and Stair Treads

In industrial settings, perforated metal sheets are used for flooring, platforms, and stair treads. The perforations provide excellent slip resistance and drainage, making them ideal for factories, construction sites, and outdoor walkways. Mild steel is often chosen for its strength and cost-effectiveness, while stainless steel is preferred for environments that require corrosion resistance, such as food processing or marine facilities.

7. Acoustic and Ventilation Panels

Perforated metal is also used in panels designed for sound control and ventilation. Acoustic panels made from perforated aluminium or steel are used in auditoriums, offices, and transport hubs to absorb sound and reduce echo. Similarly, ventilation panels in machinery or building systems allow air to pass freely while protecting equipment from damage. When it comes to perforated architecture, these panels strike a perfect balance between practicality and design flexibility.

Modern Metal for Every Sector

The versatility of perforated metal continues to grow, with applications expanding into new industries and creative disciplines. Whether it is used to create an architectural feature, a durable industrial component, or an artistic installation, this adaptable material combines strength, sustainability, and design freedom. By blending aesthetic creativity with engineering precision, perforated metal sheets are shaping the way modern structures look and perform.