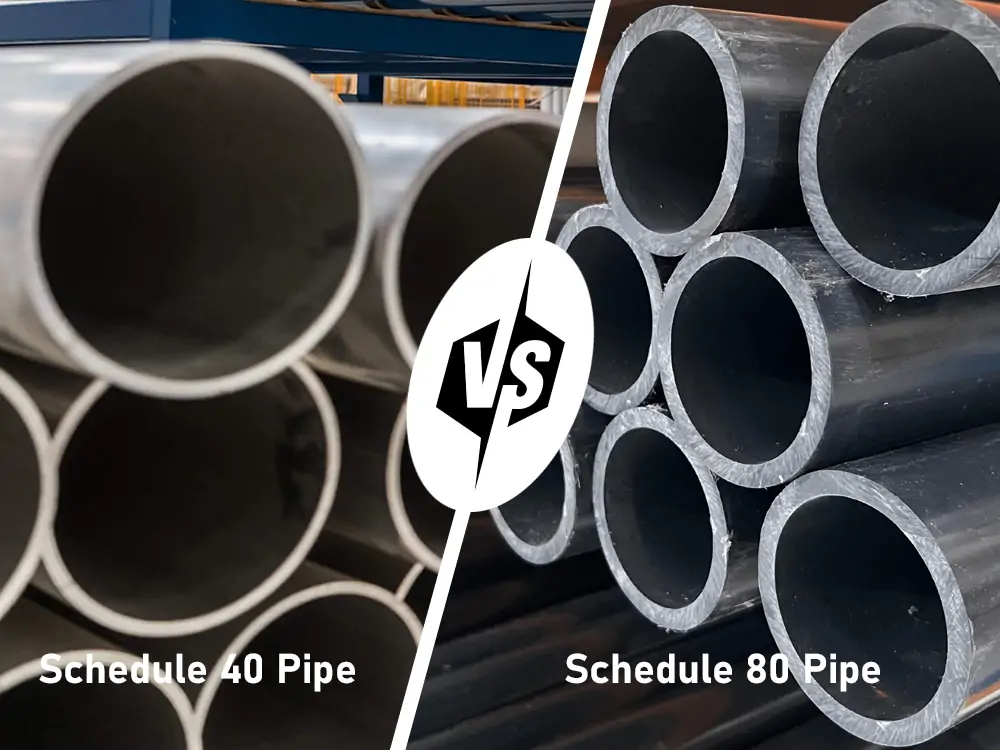

Schedule 40 vs Schedule 80 Seamless Steel Pipe

When people need seamless steel pipe for plumbing, oil and gas, construction, or industrial jobs, they often choose between Schedule 40 and Schedule 80. These are two of the most common schedules used today. They look similar from the outside, but they have different wall thicknesses, strengths, and best uses. This article explains what each one is, how they compare, where they are typically used, and how to decide which one you need.

What Does “Schedule” Mean for Steel Pipe?

The schedule number tells you the wall thickness of the pipe. It does not change the outside diameter. Two pipes with the same outside diameter can have different schedules, which means different wall thicknesses.

A higher schedule number means a thicker wall. Thicker walls make the pipe stronger and able to handle higher pressure. However, they also make the pipe heavier, more expensive, and reduce the inside diameter slightly.

Schedule 40 and Schedule 80 are the two most popular choices for seamless steel pipe. They are used in many different industries because they offer a good mix of strength, cost, and availability.

What is Schedule 40 Seamless Steel Pipe?

Schedule 40 seamless steel pipe has thinner walls compared to Schedule 80. It is considered the standard schedule for many common applications.

Wall thickness depends on the pipe size. For example:

- A 2-inch Schedule 40 pipe has a wall thickness of about 0.154 inches.

- A 4-inch Schedule 40 pipe has a wall thickness of about 0.237 inches.

Because the walls are thinner, this pipe is lighter and easier to carry and install. It also costs less than thicker schedules. The inside diameter is larger than Schedule 80 for the same outside size, which means better flow for liquids or gases.

Schedule 40 can handle normal pressure levels found in most residential, commercial, and light industrial systems. It meets many building codes and is often the default choice when extra strength is not required.

What is Schedule 80 Seamless Steel Pipe?

Schedule 80 seamless steel pipe has thicker walls than Schedule 40. The extra thickness gives it more strength and lets it handle higher pressure and tougher conditions.

Wall thickness examples:

- A 2-inch Schedule 80 pipe has a wall thickness of about 0.218 inches.

- A 4-inch Schedule 80 pipe has a wall thickness of about 0.337 inches.

The thicker wall makes the inside diameter a bit smaller, so flow is slightly reduced compared to Schedule 40. But the main benefit is higher pressure rating and better resistance to damage.

Both Schedule 40 and Schedule 80 are made seamless, meaning no weld seam. This gives them smooth inside and outside surfaces and high reliability.

Key Differences Between Schedule 40 and Schedule 80

Here is a clear comparison:

- Wall thickness — Schedule 80 is always thicker.

- Pressure capacity — Schedule 80 can handle 30–50% higher pressure (depending on size, material, and temperature).

- Weight — Schedule 80 is heavier because it uses more steel.

- Cost — Schedule 80 costs more per foot.

- Inside diameter and flow — Schedule 40 has a larger inside opening and better flow.

- Strength — Schedule 80 resists bending, impact, and external force better.

Both types follow the same manufacturing standards for seamless pipe, so the only real difference is wall thickness.

Where Schedule 40 Is Commonly Used

Schedule 40 is the go-to choice for many standard applications where pressure is moderate.

Common uses include:

- Water supply lines in homes and buildings

- Fire protection sprinkler systems

- Low- to medium-pressure natural gas lines

- General plumbing and heating/cooling systems

- Light structural supports

- Low-pressure oil and gas gathering lines

Most residential and commercial plumbing codes accept Schedule 40. It is the most economical option when you don’t need extra strength.

Where Schedule 80 Is Commonly Used

Schedule 80 is chosen when the system faces higher pressure, higher temperature, or more demanding conditions.

Typical applications include:

- High-pressure steam and hot water lines

- Hydraulic and pneumatic systems

- Process piping in chemical plants, refineries, and factories

- High-pressure oil and gas transportation lines

- Compressed air systems in industrial settings

- Areas with vibration, heavy loads, or risk of physical damage

- Underground installations that need extra durability

In many industrial projects, engineers choose Schedule 80 to add a safety factor and reduce the chance of failure.

How to Choose Between Schedule 40 and Schedule 80

Ask yourself these questions to make the right choice:

- What pressure will the pipe carry? High pressure usually means Schedule 80.

- Does the job follow a specific code or specification? Some standards require Schedule 80.

- Is maximum flow important? Schedule 40 gives better flow when pressure is low.

- What is your budget? Schedule 40 saves money when extra strength is not needed.

- Will the pipe face physical damage or rough handling? Schedule 80 holds up better.

Always check the pressure rating tables for your exact pipe size, steel grade, and operating temperature. These tables show the safe working pressure for each schedule.

If you are unsure, talk to a pipe supplier or engineer. Using the wrong schedule can cause leaks, bursts, or safety issues.

For high-quality seamless steel pipe options and professional support, check out UNIASEN.

Other Important Factors

Both schedules come in different steel grades, such as ASTM A106, A53, or API 5L. Make sure the grade matches your project needs.

You can also get them with different finishes — plain ends, beveled ends, threaded, or coated (like galvanized).

Pipe lengths are usually random 20-foot or 40-foot pieces, but custom lengths are available.

If you want to understand the basic difference between seamless and welded (seamed) steel pipe, you can learn more here.

Conclusion

Schedule 40 and Schedule 80 seamless steel pipe are both strong and reliable, but they are designed for different situations. Schedule 40 works well for most everyday jobs where cost and flow are important. Schedule 80 provides extra strength and safety for high-pressure, high-temperature, or tough environments.

Picking the correct schedule improves system performance, increases safety, and helps avoid future problems. Take time to review your project requirements so you choose the best option.