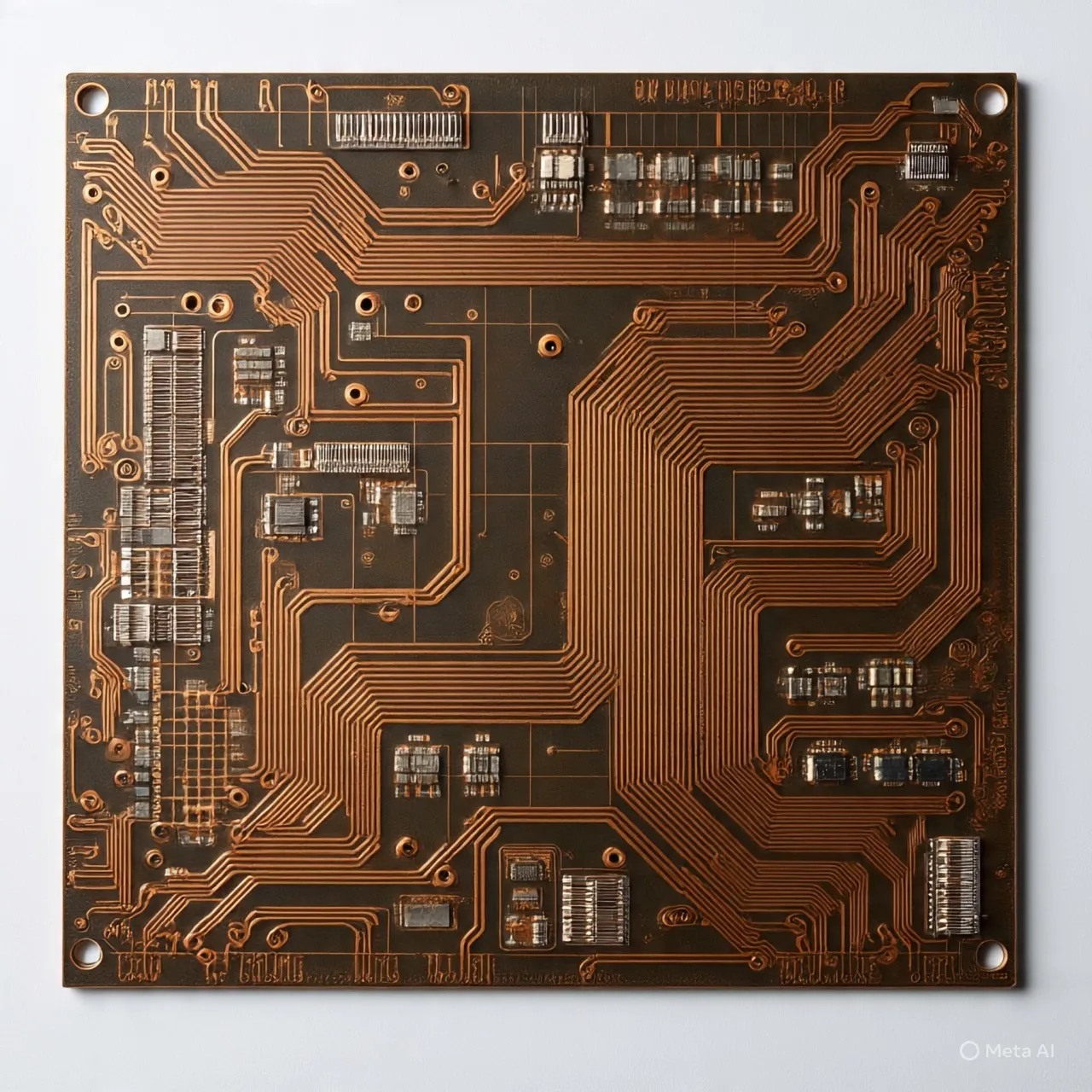

Heavy Copper PCB: 4oz and High-Current PCB Manufacturing for Power Applications

In today’s high-demand electronics industry, standard printed circuit boards often fall short when it comes to handling high currents and heat dissipation. That’s where heavy copper PCBs come into play. These boards, designed to carry large amounts of current while maintaining structural integrity, have become a go-to solution in power electronics, industrial machinery, and automotive applications. As a China-based thick copper PCB manufacturer, we specialize in delivering reliable, high-performance heavy copper PCB fabrication—from 3 oz to 20 oz copper layers—ensuring your project meets even the most demanding power requirements.

What Makes Heavy Copper PCBs Different?

Unlike conventional PCBs, which typically use copper layers ranging from 1 oz to 2 oz, heavy copper PCBs are engineered with significantly thicker copper layers, often 4 oz or more. This extra copper thickness allows these boards to:

- Handle higher current loads without excessive heating

- Improve thermal management for sensitive components

- Increase mechanical strength for rugged applications

From my experience working with clients in industrial and automotive electronics, the difference is night and day. Standard boards might warp or fail under high currents, but heavy copper PCBs remain stable, reliable, and safe.

Applications of 4oz and High-Current PCBs

High-current and 4oz copper PCBs are widely used in applications where electrical performance and durability are critical. Some of the most common uses include:

Power Conversion Systems

Devices like inverters, converters, and UPS systems rely heavily on thick copper PCBs to handle high currents efficiently. The thicker copper layers help reduce resistive losses and improve overall efficiency.

Automotive Electronics

Modern vehicles, especially electric and hybrid cars, demand robust PCB solutions. Heavy copper PCBs provide the high current capacity required for battery management systems, motor controllers, and charging modules. Personally, I’ve seen how switching to 4oz copper PCBs in automotive prototypes dramatically reduces heat-related failures during testing.

Industrial Equipment

Industrial machinery, including robotic arms, CNC machines, and power supply units, operates under heavy electrical loads. High-current PCBs ensure long-lasting performance and minimal maintenance, making them indispensable for reliable industrial operations.

Why Choose a Thick Copper PCB Manufacturer?

Choosing the right thick copper PCB manufacturer is essential for the success of any high-power electronics project. A reliable manufacturer not only delivers quality boards but also provides:

- Custom fabrication options: From 3 oz to 20 oz copper layers, tailored to your requirements

- Rapid prototyping: Quick-turn services to test your designs before mass production

- Competitive pricing: Cost-effective solutions without compromising quality

As a manufacturer based in China, we’ve worked with hundreds of clients worldwide, delivering boards that meet both international standards and customer expectations. Upload your Gerber files now for a fast, competitive quote, and see how smooth the process can be.

Key Advantages of Heavy Copper PCBs

Investing in heavy copper PCBs offers multiple benefits over standard boards:

Enhanced Current-Carrying Capacity

Thicker copper layers allow boards to carry higher currents safely. This is critical in power electronics where even small resistive losses can lead to overheating and component failure.

Superior Heat Dissipation

High-current applications generate significant heat. Thick copper PCBs spread the heat more efficiently, reducing hotspots and prolonging the life of your components.

Mechanical Strength and Durability

Heavy copper layers not only improve electrical performance but also add rigidity to the PCB. This is particularly valuable in automotive and industrial applications, where boards are exposed to vibration, stress, and harsh environments.

Reduced Voltage Drop

With thicker copper, the resistance decreases, minimizing voltage drops across the board. This improves the overall efficiency of power delivery in critical applications.

Design Considerations for High-Current PCBs

When designing high-current PCBs, several factors must be considered to maximize performance:

- Copper thickness selection: Decide based on current requirements; 4oz copper is common, but some power applications may require even thicker layers.

- Thermal management: Use thermal vias and planes to optimize heat dissipation.

- Trace width calculation: Wider traces help distribute current evenly and reduce hotspots.

- Surface finish options: Choose finishes that enhance solderability and reliability under high current conditions.

Personally, I always recommend consulting with a heavy copper PCB manufacturer during the design phase. Their experience can prevent costly mistakes and ensure the final board meets performance expectations.

Manufacturing Capabilities

As a thick copper PCB manufacturer, our services cover the full spectrum of heavy copper fabrication:

- Layer range: From 1-layer prototypes to multi-layer 20 oz boards

- Copper thickness: Customizable from 3 oz to 20 oz for power and industrial applications

- High-precision etching: Ensures tight tolerances even with thick copper layers

- Quick-turn prototyping: Rapid fabrication to keep your projects on schedule

We’ve found that clients appreciate our transparent communication and hands-on approach. Sharing feedback early in the process often results in better outcomes and smoother production runs.

Tips for Working with Heavy Copper PCBs

For engineers and designers new to heavy copper PCBs, a few practical tips can make a big difference:

- Plan for heat: Always design with thermal management in mind; thick copper spreads heat but doesn’t eliminate it.

- Use proper connectors: Ensure all connectors and solder joints can handle the intended current.

- Test prototypes thoroughly: Before mass production, validate your design under actual load conditions.

- Collaborate with the manufacturer: Leverage their expertise in layout, trace width, and copper thickness optimization.

I’ve personally seen many projects avoid failure simply by consulting with an experienced manufacturer before finalizing their PCB design. It saves time, money, and headaches.

Conclusion

In the rapidly evolving world of power electronics, relying on standard PCBs can be risky. Heavy copper PCBs, including 4oz copper and high-current designs, provide the durability, reliability, and performance necessary for today’s demanding applications. As a China-based thick copper PCB manufacturer, we specialize in delivering robust, high-quality boards from 3 oz to 20 oz copper layers, tailored for power conversion, automotive, and industrial electronics.