Relative Advancements of Electronic Components and Influence to the Electronics World Today

The boundless pace of change in the electronics sector and its design, manufacturing, and use of component changes across multiple markets. Within these cross section markets, B2B service providers within the system automation, consumer electronics, automotive, and telecommunication sectors have to be aware of recent market changes in electronic components. These technologies, along with sophisticated components and technological tools, will aid the B2B service providers greatly in slashing operational costs while improving their overall operational efficiency.

B2B electronic manufacturers like OMCH, greatly assist their customers in achieving these objectives adjusting operational objectives to emerging markets. This electronic manufacturer provides components and solutions along with manuals on market emerging technologies, enabling operational efficiency, and product integrities optimization. This article will focus on operational objectives emerging technologies and evolving electronics components in electronics mobile learning applications.

The miniaturization of components and their high density integration cabinets, is one of the trends boasting of modern electronics. The highest on the scale of these electronic components is a strong, ever growing demand, for all types of mobile electronics to be made more compact. The most dense type of integration of many functions into one component, with the lowest number of other components, within a given system, is called high density integration.

One of the more powerful tested trends, which Impact B2B manufacturers best, is the ability to miniaturize components also the highest demand is.

Space efficiency: A device is easier to carry and transport when it is smaller and lighter.

Cost reduction: There is less material and time spent to build the device since it has fewer parts.

Enhanced functionality: Becoming part of the system makes these devices able to perform multiple tasks which improves the system’s overall productivity.

Using miniaturized designs, B2B businesses can enhance functionalities and lower costs when buying from an electronic components vendor. Multifunctional electronics of high density and miniaturization can be complex and OMCH specializes in providing multifunctional tailored solutions.

Sustainable and energy efficient components

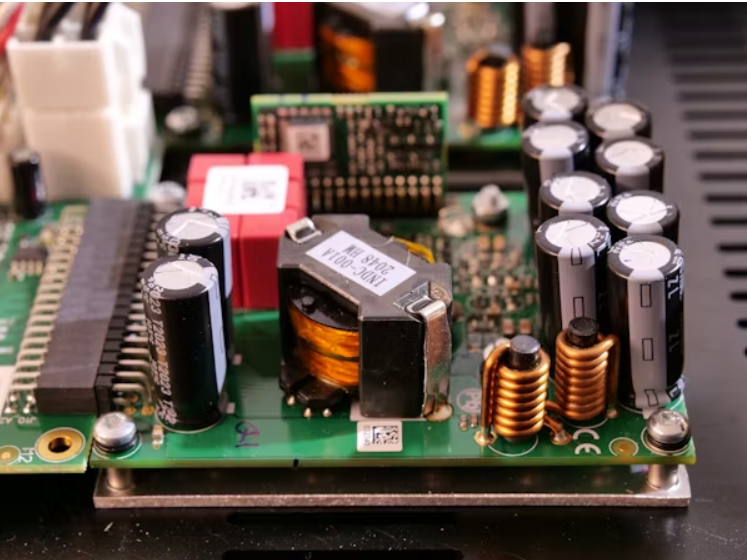

Sustainable electronics consider the ecological consequences and energy used by the device. Every element from semiconductors to passive components such as capacitors and resistors becomes affected, owing to high performance standards and low consumption objectives.

Principal innovations consist of:

Low- power ICs: Integrated circuits designed to use minimal energy to function.

High Efficiency Power Modules: Modules that improve the overall efficiency of the system during the regulation of voltage and power.

Eco-friendly materials: Components that contain less toxic substances and are easier to recycle

B2B employees in the manufacturing domain gain compliance to energy efficient standards when OMCH parts are used. This is achieved by adhering to legal and operational boundaries, minimizing business costs, and fulfilling the firm’s social responsibility objectives.

Modern Connectivity and the Internet of Things

Increased inter-device connectivity and communication has accelerated the demand for new electronic components. Integrated network systems with wireless communication and high-speed data transfer require advanced components.

Some of the recent trends in connectivity-related components include:

RF modules and antennas. Providing wireless link capabilities for IoT devices.

High-speed data interfaces. Supporting real-time data processing by enabling rapid transmission.

Smart sensors. Acting as data sources for sophisticated systems that require real-time information processing.

OMCH B2B Enterprises with an electronic components company IoT-ready component helps device manufacturers offer seamless advanced connectivity for next-gen applications with smart IoT devices.

Ruggedness and Industrial Grade Components

The growing demand for reliable and sturdy industrial electronic components for deployment in extreme conditions has also increased. Components designed for industrial use can withstand extreme temperatures, vibrations, and electromagnetism.

The main benefits of increased component reliability include:

Decreased lifecycle costs. Reduced maintenance and replacements with longer lasting components.

Increased safe operation. Components mitigate system adverse effect failures during operation.

Disturbance interval: The high grade materials used in these industrial systems minimises the chances of facing random stoppages.

SP Company and others in the B2B domain are able to procure industrial grade equipment from OMCH and integrate it niche products such as SP Company and others in the B2B domain are able to procure industrial grade equipment from OMCH and integrate it nich products. OMCH is a supplier that offers components that have been tested for diverse and extreme conditions to assure reliability under rigorous conditions.

Novel Materials and Associated Breakthroughs

New materials and other paradigm change designs are modifying the use and performance of electronic components. The use of sophisticated polymers and nanostructured materials for the synthesis of compact and high performance devices and the enhancement of thermal management are of great importance.

Some other noteworthy advances are:

Gallium nitride (GaN) devices: The development of high power transistors and diodes with improved efficiency and power density.

Foldable electronics: Technology that allows the bending and folding of connected circuits preserving balanced performance.

Advanced thermal engineering: Specialisation in high power devices that are compact in size and miniaturised components with superior heat dissipation.

Businesses focusing on B2B sales especially have to adopt these innovations as a must to stay competitive. With best size, speed, and reliability metrics and cutting-edge materials to gain a competitive advantage, partnering with an electronic components manufacturer is a no-brainer. Providers like OMCH continually incorporate newer technologies into their products, expanding their component offerings and meeting market demands.

Conclusion

In the electronic components market, refining work practices is needed as it has become harder to gain and maintain a competitive advantage. In the field of electronics design and manufacturing, energy efficiency, industrial-grade reliability, iot, and even advanced materials modular capable design and manufacturing of electronics these are the essential pillars.

Companies like OMCH and their trusted partners support B2B electronic components customers to keep up and leverage the new technologies to design high intelligence, outperforming and reliable products. With these technologies, businesses can operationalize their sustainability goals, increasing performance, lowering operating costs, and shifting to a responsive flexible supply to market demands.For a B2B organization, mastering and adopting current trends in electronic components will give them a much-needed edge during downtimes and nurture the much-needed innovation to stay the market leader and offer cutting-edge electronics.